PVC (Polyvinyl Chloride) extrusion is a high-volume manufacturing process used to form continuous profiles by melting raw PVC plastic. PVC is the most commonly extruded rigid plastic. It is cheap, exhibits recyclable properties, and is versatile for use in both indoor and outdoor environments. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Crafted Plastics Inc. open_in_new

Location: Sheboygan, WI

Crafted Plastics has served the plastics extrusion needs of manufacturers and distributors worldwide since 1982. We craft plastics from a wide array of thermoplastics and are able to extrude basic to complex profiles. Whether you need products made from polyethylene, polycarbonate, polypropylene, PVC or acrylic, we’re your source for extruded plastic profiles or tubing. Call us soon; we look...

Pexco open_in_new

Location: Alpharetta, GA

Pexco has been a leader in custom plastic extrusion and injection molding, delivering innovative solutions for diverse markets and applications. We have six in-house tool and die centers and expertise in processing over 500 different resins and blends. We specialize in high-performance fluoropolymers, thermoplastics, and elastomers, delivering reliable performance in the most demanding...

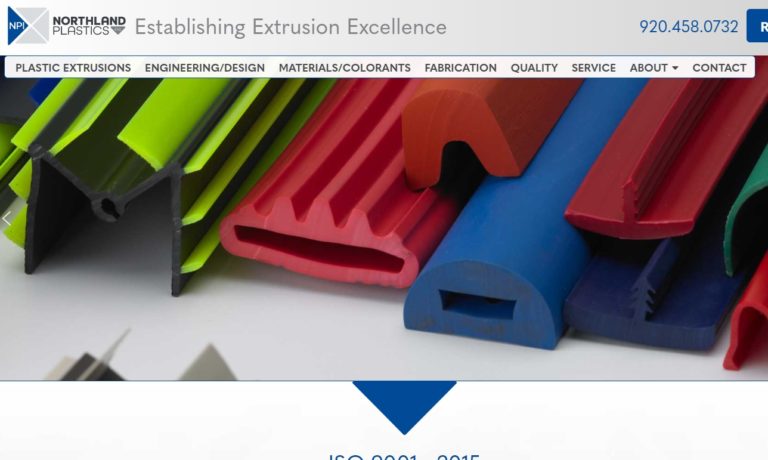

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More PVC Extrusion Manufacturers

Consequently, rigid PVC extrusions are a popular choice for various industrial, commercial, and residential applications. PVC, or polyvinyl chloride, is a hard thermoplastic polymer that can be further enhanced using impact modifiers for increased durability and flexibility. Extrusions made from rigid PVC exhibit strong chemical resilience, meaning that rigid PVC tubing, profiles, and sections can be easily welded, glued, and fused—an essential feature for creating reliable joints in piping systems and structural assemblies.

Extruded rigid PVC profiles, trims, and structural sections are especially suitable for outdoor environments due to their high corrosion resistance, UV stability, and weatherproofing qualities. In addition, PVC's excellent electrical insulation properties make it ideal for low-voltage electrical applications, cable management systems, and protective conduit installations. Thanks to these numerous benefits, rigid PVC extrusions are used successfully in both outdoor and indoor locations, supporting industries like construction, automotive manufacturing, marine engineering, retail, and more.

How Are PVC Extrusions Manufactured?

PVC extrusions are produced using a precise and efficient process that transforms raw PVC material into continuous, custom-shaped products. The process begins with feeding PVC pellets or powder—sometimes combined with additives like stabilizers and plasticizers—into a PVC twin-screw extruder. This specialized extrusion machine uses rotating screws to convey, melt, and mix the raw material as it passes through multiple extruder zones, each carefully temperature-controlled to ensure a consistent melt.

Once the PVC material reaches the optimal viscosity, it is forced through a shaped die, which determines the cross-sectional profile of the final product—whether it's a pipe, tube, trim, channel, or custom profile. The hot extrudate immediately enters a cooling system, often involving water baths or air cooling, to solidify the shape and preserve dimensional accuracy. For pipe or tubing applications, the extruded PVC is then cut into specified lengths, ready for further fabrication or assembly.

Curious about the technical aspects? Explore: How does a twin-screw extruder improve PVC extrusion quality and efficiency?

Types of PVC Extrusions: Rigid vs. Flexible and More

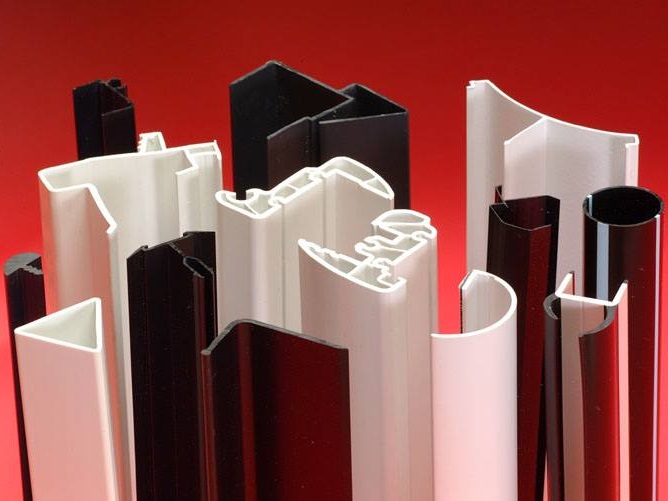

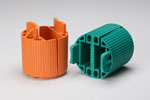

The versatility of the PVC extrusion process allows for the creation of a wide range of products tailored to diverse industry needs. The main types of PVC extrusions include:

Flexible PVC Extrusions

Flexible PVC (polyvinyl chloride) is formulated by incorporating plasticizers that make the material softer, more pliable, and easier to bend than rigid PVC. This flexibility is essential for applications such as electrical wire insulation, cable jacketing, flexible tubing, and gaskets. Flexible PVC extrusions are also widely used in the flooring industry, where their resilience and ease of cleaning make them a top choice for both commercial and residential settings. Other typical uses include weatherstripping, door seals, and protective edge trims.

Rigid PVC Extrusions

Rigid PVC, often referred to as uPVC (unplasticized polyvinyl chloride), is the most commonly used form in the extrusion industry. Renowned for its strength, low weight, and dimensional stability, rigid PVC extrusions are the backbone of countless construction and infrastructure projects. They are easily welded using thermoplastic welding equipment and can be fabricated into window and door frames, wall panels, decking systems, fencing, cladding, and piping.

In addition to the construction sector, rigid PVC is invaluable in automotive, marine, and agricultural industries for components such as body trims, dashboard profiles, boat rails, and irrigation pipes. The material's chemical resistance and weatherproof properties ensure long service life with minimal maintenance.

PVC Tubing and Custom Plastic Tubing

The majority of plastic tubing used across industries is manufactured from extruded PVC. This process produces tubing that is highly resistant to chemicals, corrosion, and abrasion, making it ideal for fluid transport, pneumatic systems, medical applications, and food processing. PVC tubing is available in a variety of shapes—including round, square, and oval cross-sections—and can be tailored for specific performance requirements such as flexibility, pressure resistance, and clarity. Square plastic tubing, for instance, is commonly used in framing, supports, and display structures.

Looking for custom shapes? Discover: How can custom PVC extrusions meet your specific project requirements?

Key Applications of PVC Extrusions Across Industries

- Construction Industry: Rigid PVC extrusions are widely used for water and drainage pipes, cladding, soffits, gutters, downspouts, conservatories, window frames, door jambs, wall and door protection, skirting boards, and cable trunking. The excellent thermal insulation, moisture resistance, and stability of rigid PVC make it a go-to material for builders and architects seeking durable, cost-effective building solutions.

- Transportation: PVC extrusions are used externally for vehicle bodies, RVs, caravans, and boats thanks to their lightweight, corrosion-resistant nature. Internally, they serve as decorative trims, dashboard profiles, seat edge guards, and panel retainers, offering both functionality and improved aesthetics. The availability of multiple colors and surface finishes enables seamless integration with interior and exterior designs.

- Retail and Display: In the retail sector, PVC extrusions form the backbone of point-of-purchase displays, ticket strips, poster grippers, display shelves, and storage racks. Their ease of customization and ability to hold vibrant colors make them ideal for marketing and merchandising environments.

- Electrical and Cable Management: Due to their outstanding dielectric properties and flame retardancy, PVC extrusions are utilized for electrical conduit, wire insulation, trunking, and protective covers—ensuring safety and regulatory compliance.

- Medical, Food, and Laboratory: Medical-grade PVC extrusions are used for tubing, catheters, and enclosures, owing to their biocompatibility, chemical resistance, and ease of sterilization. In food processing, PVC is chosen for fluid handling, cleanroom dividers, and hygienic surfaces.

- Industrial and Agricultural: PVC extrusions are found in machinery guards, irrigation pipes, greenhouse profiles, conveyor guides, and storage bins, supporting efficient operations in manufacturing plants and farms.

Need application-specific guidance? Ask: Which type of PVC extrusion is best for my industry or project?

Benefits of PVC Extrusions: Why Choose PVC for Your Project?

The popularity of PVC extrusions is driven by their unique combination of performance, process efficiency, and cost-effectiveness. Key advantages include:

High-Speed, High-Volume Production at Low Cost

The continuous extrusion process allows manufacturers to produce large quantities of custom profiles, pipes, and tubing with remarkable speed and minimal material waste. Unlike other fabrication methods, extrusion requires lower tooling costs and is highly scalable, making it ideal for both short and long production runs. The efficiency of PVC extrusion is a decisive factor for industries seeking to optimize lead times and reduce expenses without compromising quality.

Design Versatility and Customization

PVC extrusion is an inherently flexible manufacturing process, enabling the creation of profiles with complex shapes, variable thicknesses, and intricate detailing. Products can be made in virtually any color or surface texture, from glossy to matte, to suit branding and functional requirements. Additives can be introduced to enhance UV resistance, antimicrobial properties, flame retardancy, and impact strength, ensuring the final product meets specific performance standards.

Post-Extrusion Alterations and Fabrication

After extrusion, PVC products retain enough heat and plasticity to allow for secondary operations—such as bending, shaping, punching, drilling, and notching—without risking cracks or deformation. This post-extrusion workability ensures that even complex designs can be efficiently produced and finished to precise tolerances.

Environmental Sustainability and Recycling

Modern PVC extrusion processes are increasingly sustainable. Many manufacturers incorporate recycled PVC content into their products or use energy-efficient equipment to reduce environmental impact. PVC itself is recyclable, and off-cuts or excess material from the extrusion line can be reground and reused. For organizations prioritizing eco-friendly solutions, PVC extrusions offer a balance between performance and sustainability.

Durability and Longevity

PVC extrusions are renowned for their long service life, resistance to corrosion, and ability to withstand harsh environmental conditions. These qualities reduce maintenance demands and replacement costs over time, making PVC a reliable investment for high-traffic, high-wear, or exposed installations.

Comparing manufacturing options? Explore: How does PVC extrusion compare to injection molding for custom plastic parts?

Disadvantages and Limitations of PVC Extrusions

While PVC extrusions offer many advantages, there are important considerations to keep in mind. The inherent properties of PVC plastic mean that extrusion equipment is subject to high friction and thermal stress, especially at elevated processing temperatures. As a result, production lines for PVC extrusions require specialized, robust machinery—typically twin-screw extruders made from wear-resistant alloys—to ensure consistent product quality and long service life.

Additionally, PVC can degrade if not processed under controlled conditions, potentially releasing fumes or causing discoloration. Manufacturers must implement strict quality control measures and proper ventilation to mitigate these risks. For some high-temperature or high-pressure applications, alternative materials like polyethylene (PE), polypropylene (PP), or specialty thermoplastics may be more suitable.

Wondering about material selection? Read: When should you choose PVC extrusion over other plastic extrusion materials?

How to Choose the Right PVC Extrusion Manufacturer

Selecting the optimal PVC extrusion supplier is critical to achieving project success, whether you're sourcing standard products or highly customized solutions. To make an informed decision, consider the following factors:

- Experience and Capabilities: Look for manufacturers with a proven track record in your industry and the ability to produce the specific PVC extrusions you require—whether that's rigid, flexible, clear, colored, or specialty profiles.

- Customization Options: Evaluate the company's ability to support custom tooling, unique designs, co-extrusion (combining multiple materials), and specific finishing or secondary operations.

- Material Quality and Compliance: Ensure the supplier sources high-grade PVC compounds and can certify compliance with relevant industry standards—such as ASTM, ISO, UL, or FDA—depending on your application.

- Production Capacity and Lead Times: Assess the manufacturer's ability to meet your volume requirements and deliver on schedule, especially for large-scale or time-sensitive projects.

- Customer Support and Technical Guidance: Choose a partner who provides clear communication, technical advice, and responsive service throughout the specification, prototyping, and production process.

- Sustainability Practices: Inquire about the use of recycled materials, waste reduction initiatives, and environmentally responsible manufacturing processes.

To ensure you have the most productive outcome when purchasing PVC extrusions from a PVC extrusion manufacturer, it is important to compare several companies using our directory of PVC extrusion manufacturers. Each PVC extrusion manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each PVC extrusion business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple PVC extrusion companies with the same form.

Ready to start your search? Try: Find and compare leading PVC extrusion suppliers near you or request quotes for your custom PVC extrusion project.

Frequently Asked Questions About PVC Extrusions

What are the most common uses for PVC extrusions?

PVC extrusions are widely used in construction, electrical, automotive, marine, retail, and medical industries. Typical applications include window and door frames, pipes and tubing, cable management systems, display components, and custom profiles for manufacturing and assembly.

How do I select the right PVC extrusion for my project?

Consider your project's environmental conditions, mechanical requirements, regulatory standards, and desired aesthetics. Consulting with an experienced PVC extrusion manufacturer can help you specify the right material grade, profile geometry, color, and any necessary additives or finishing processes.

Can PVC extrusions be recycled?

Yes, PVC extrusions are recyclable. Scrap material from manufacturing can be reground and reused, and many finished PVC products can be collected and recycled at end of life. Ask your supplier about their recycling and sustainability practices.

What customization options are available for PVC extrusions?

Customization options include unique cross-sectional shapes, co-extrusion with multiple materials, a wide range of colors and finishes, the integration of additives (for UV resistance, flame retardancy, antimicrobial properties), and secondary operations like drilling, punching, or embossing.

What are the key advantages of working with a specialized PVC extrusion company?

Partnering with a specialized manufacturer ensures access to advanced extrusion technology, material expertise, and comprehensive support from design to delivery. This leads to higher quality products, faster turnaround times, and greater flexibility in meeting complex or high-volume requirements.

Still have questions about PVC extrusions or need technical support?Contact our team for expert advice and solutions.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services