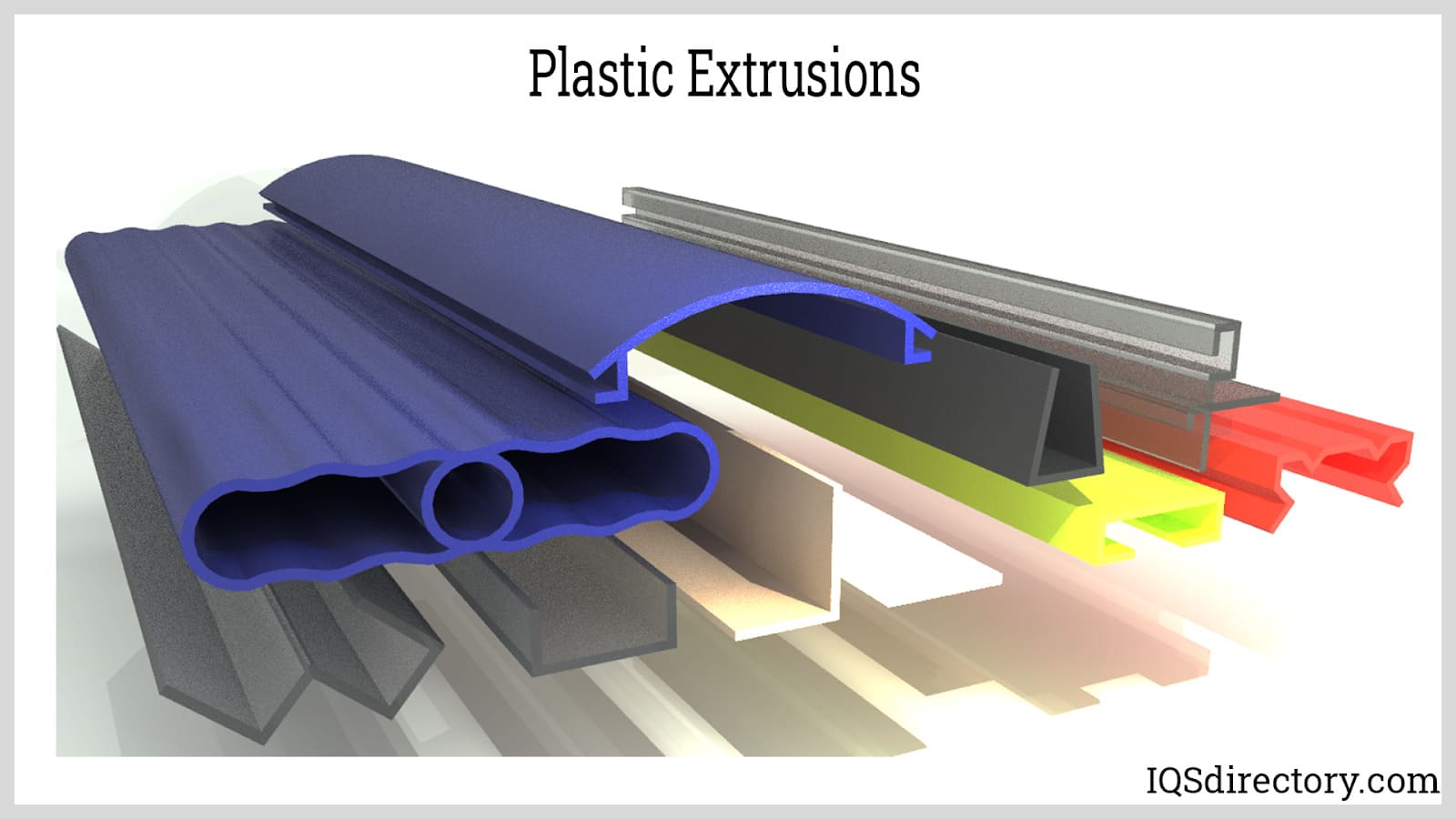

Polymer extrusion is a process whereby a molten polymer is used to create components of a fixed cross-sectional area by forcing it through a die. The components include tubes and rods.Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Crafted Plastics Inc. open_in_new

Location: Sheboygan, WI

Crafted Plastics has served the plastics extrusion needs of manufacturers and distributors worldwide since 1982. We craft plastics from a wide array of thermoplastics and are able to extrude basic to complex profiles. Whether you need products made from polyethylene, polycarbonate, polypropylene, PVC or acrylic, we’re your source for extruded plastic profiles or tubing. Call us soon; we look...

Pexco open_in_new

Location: Alpharetta, GA

Pexco has been a leader in custom plastic extrusion and injection molding, delivering innovative solutions for diverse markets and applications. We have six in-house tool and die centers and expertise in processing over 500 different resins and blends. We specialize in high-performance fluoropolymers, thermoplastics, and elastomers, delivering reliable performance in the most demanding...

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Polymer Extrusion Manufacturers

Understanding the Polymer Extrusion Process: Methods, Applications, and Industry Insights

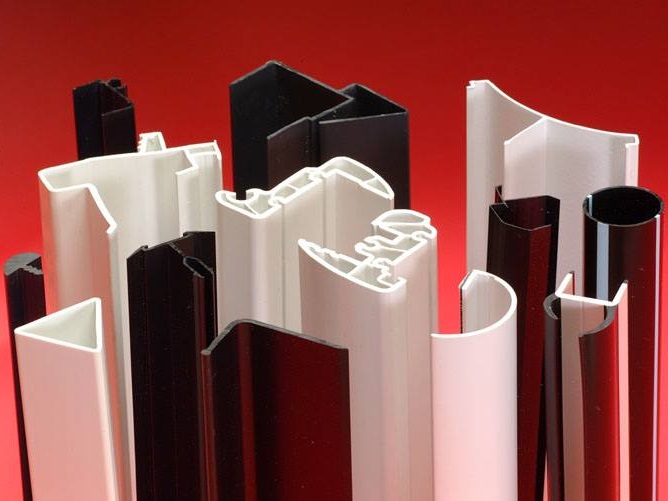

Polymer extrusion is a cornerstone of modern plastic manufacturing—a highly versatile, cost-effective, and scalable process used to produce an extensive range of plastic products and components. From medical tubing and packaging films to window frames and custom plastic profiles, extrusion technology enables manufacturers to efficiently create long, continuous shapes with precise, repeatable cross-sections. If you're researching plastic extrusion or seeking the right polymer extrusion company, understanding the full scope of extrusion methods, applications, benefits, and selection criteria is vital for informed decision-making.

The Polymer Extrusion Process: Step-by-Step Overview

The core principle behind polymer extrusion is the transformation of raw thermoplastic or thermoset resins into continuous profiles of a desired shape and size. This is accomplished by forcing softened polymer—typically in the form of pellets or granules—through the precisely engineered opening of a die. Here’s how the process unfolds:

- Material Feeding: Polymer pellets are loaded into an extruder via a hopper.

- Melting: The pellets are conveyed forward by a rotating screw inside a heated barrel. Heating elements and thermocouples ensure precise temperature control, softening and melting the polymer to a uniform viscosity.

- Extrusion: The molten polymer is forced through a custom die to create a continuous product with a constant cross-sectional profile.

- Shaping and Cooling: Upon exiting the die, the hot extrudate is rapidly cooled and solidified by blown air, water baths, or cooling rolls, depending on the application.

- Cutting and Finishing: The continuous product is cut to length or wound for further processing, such as printing, forming, or assembly.

Polymer extrusion is a continuous, high-output process that remains operational as long as raw materials are supplied. While most commonly associated with thermoplastics like polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), extrusion can also be applied to thermosetting plastics and elastomers. In these cases, cross-linking occurs within the extruder as the material is heated and shaped.

Looking for more detail?

What is the difference between single-screw and twin-screw extruders?

Single-screw extruders are ideal for basic, homogeneous materials and straightforward product geometries. Twin-screw extruders provide improved mixing, higher throughput, and better handling of complex or multi-component formulations, such as in co-extrusion and compounding applications.

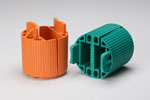

Types of Polymer Extrusion Methods

Extrusion technology offers several process variants, each tailored to specific product requirements, material types, and end-use applications. Understanding these major extrusion types helps you identify the best solution for your project:

Tubing Extrusion

Tubing extrusion is used to manufacture pipes, tubes, and hollow profiles with consistent wall thickness. In this process, air is introduced under positive internal pressure to maintain the tube’s shape as it exits the die. The hot extrudate is then cooled—usually in a water bath—to set the dimensions and improve surface finish. Tubing extrusion is critical for producing medical tubing, irrigation pipes, and various conduit products.

Blown Film Extrusion

Blown film extrusion is a specialized technique for manufacturing thin, flexible plastic films used in packaging, protective wraps, and shopping bags. In this process, a molten tube of polymer is extruded vertically, then inflated with air to create a “bubble.” The bubble is drawn upward, cooled, and collapsed into flat film. This method yields high-quality films with uniform thickness and excellent mechanical properties. Key applications include food packaging, agricultural films, and retail bags.

Sheet and Film Extrusion

Sheet extrusion produces thicker plastic sheets (>0.25 mm) or thin films (<0.25 mm) by forcing molten polymer through a flat die. The extrudate is pulled through a series of polished cooling rolls that set the thickness and surface texture. Sheet and film extrusion is widely used in thermoforming, signage, packaging, and construction panels, where precise control of thickness and surface quality is crucial.

Over Jacket Extrusion (Wire and Cable Coating)

Over jacket extrusion, also known as wire coating extrusion, is used to insulate and protect electrical wires and cables. In this process, a conductor is drawn through the die’s center while molten plastic is applied around it. Depending on the required adhesion, either pressure tooling (for bonded coatings) or jacket tooling (for loose coatings) is used. Over jacket extrusion delivers durable, moisture-resistant insulation for telecommunications, automotive, and electronic wiring.

Co-Extrusion and Multi-Layer Extrusion

Co-extrusion allows manufacturers to combine two or more polymers into a single, multi-layer product. By using multiple extruders feeding into a single die, co-extrusion creates products with tailored properties—such as strength, barrier resistance, and aesthetics—while optimizing material costs. This method is especially popular in packaging films, window profiles, and composite decking materials.

Want to compare extrusion types for your application?

Ask yourself: What end-use environment, mechanical properties, or regulatory requirements does your product need to meet? Reach out to polymer extrusion companies for application-specific recommendations.

Common Applications of Polymer Extrusions

The versatility of plastic extrusion enables its use across a diverse array of industries. Here are examples of real-world applications and product types manufactured via extrusion technology:

- Medical and Pharmaceutical: IV tubing, catheter sheaths, fluid transfer lines, and diagnostic device components.

- Construction: Vinyl siding, window frames, weatherstripping, and architectural trims.

- Infrastructure: Drainage, irrigation, and conduit pipe; cable jacketing for power and telecom.

- Consumer Products: Furniture trim, curtain rails, garden hoses, and decorative moldings.

- Packaging: Blown films for food bags, shrink wrap, pallet covers, and barrier films.

- Automotive: Weatherseals, wire insulation, and under-hood tubing.

- Industrial: Conveyor guides, machine guards, and chemical-resistant liners.

Which industries benefit most from custom extrusion solutions?

Medical, automotive, electronics, and construction sectors frequently specify custom plastic extrusions to meet stringent performance, dimensional, and regulatory requirements. If you have a unique profile or need specialized material properties, partnering with an experienced extrusion manufacturer is essential.

Advantages and Benefits of Polymer Extrusion

Choosing polymer extrusion offers a wide range of advantages, especially for businesses seeking efficient, high-quality production of plastic components:

- Continuous, High-Volume Production: Extrusion supports long, uninterrupted runs, making it ideal for manufacturing miles of pipe, tubing, or film with consistent quality.

- Cost Efficiency: High throughput and automation lower per-unit costs compared to other forming methods. Co-extrusion further reduces costs by incorporating recycled or reground materials.

- Design Flexibility: Complex shapes, varied textures, multi-layer structures, and embedded colors can be achieved with the correct die and process settings.

- Post-Extrusion Customization: The hot extrudate can be shaped, punched, slit, or embossed before final cooling. This enables a wide range of secondary operations and customizations.

- Material Versatility: Compatible with most thermoplastics (PVC, PE, PP, ABS, PETG, etc.), thermosets, elastomers, and engineered polymers.

- Enhanced Product Properties: Multi-layer or reinforced extrusions can offer improved strength, flexibility, chemical resistance, or barrier performance.

- Environmental Advantages: Many extrusion processes can use recycled plastics, supporting sustainability goals and reducing material waste.

Questions to Consider When Choosing Extrusion

- What is the required shape, size, and tolerance of your finished product?

- Which material properties (strength, flexibility, clarity, chemical resistance) are most critical?

- Are regulatory or industry certifications needed (e.g., FDA, NSF, UL)?

- What is your target production volume and run length?

- Do you require multi-layer, co-extruded, or custom-colored products?

How to Select the Best Polymer Extrusion Company for Your Project

Choosing the right polymer extrusion supplier is key to achieving your quality, cost, and delivery goals. When evaluating potential extrusion partners, consider the following:

- Technical Capabilities: Does the company offer the specific extrusion methods you need (tubing, sheet, blown film, co-extrusion)?

- Material Expertise: Are they experienced with your required polymers or specialty materials?

- Customization and Design Support: Can they assist with die design, material selection, and prototyping?

- Certifications and Quality Systems: Do they meet industry standards for medical, food, or automotive applications?

- Production Capacity and Lead Times: Can they support your volumes and delivery schedules?

- Customer Service and Communication: Do they provide clear quotes, samples, and responsive support?

Use our comprehensive directory of polymer extrusion companies to compare suppliers. Each listing features detailed business profiles, highlights of technical expertise, and direct contact forms for quote requests or information. Leverage our patented website previewer feature to quickly assess each company’s specialties, then use our simple RFQ system to reach multiple suppliers at once—saving you time and expediting your search for the ideal extrusion partner.

Key Decision Factors for Polymer Extrusion Projects

- Product complexity and required tolerances

- Material compatibility and regulatory compliance

- Cost structure and production efficiency

- Scalability for future orders

- Supplier location and logistics

- Value-added services (e.g., assembly, packaging, secondary machining)

Not sure how to start your supplier search?

Try filtering our directory by industry or extrusion capability, or reach out with your project requirements for personalized recommendations.

How do you evaluate quotes from different extrusion companies? Compare not just pricing, but also tooling costs, minimum order quantities, lead times, and included support services.

Frequently Asked Questions About Polymer Extrusion

What polymers are most commonly extruded?

Commonly extruded thermoplastics include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and specialty materials such as thermoplastic elastomers (TPE) and fluoropolymers (e.g., PTFE). Each polymer offers unique characteristics in terms of flexibility, strength, chemical resistance, and clarity.

What is the difference between extrusion and injection molding?

Extrusion is best suited for producing long, continuous shapes (tubing, profiles, films), while injection molding is ideal for discrete, complex 3D parts. Extrusion processes are continuous, while injection molding is a cyclic, batch-oriented process. Each method offers unique advantages based on application and production volume.

How does co-extrusion reduce costs?

Co-extrusion allows the use of lower-cost or recycled materials in the product core, surrounded by a virgin or specialty polymer outer layer for performance. This reduces raw material costs without sacrificing product quality, and is widely used in fencing, decking, and packaging films.

Can extruded products be recycled?

Many extruded plastics are recyclable, both as scrap generated during production and at end-of-life. Some extrusion companies actively integrate recycled content into new products, supporting circular economy and sustainability initiatives.

What is the minimum order quantity for custom extrusion?

Minimum order quantities (MOQs) vary by supplier, material, and product complexity. Some manufacturers support small prototype runs, while others focus on high-volume production. Always confirm MOQs and lead times with your shortlisted extrusion companies before starting a project.

Emerging Trends in Polymer Extrusion

As industries demand greater performance and sustainability, extrusion technology is evolving rapidly. Notable trends include:

- Advanced Materials: Increased use of bio-based polymers, high-performance engineering plastics, and nanocomposites in extrusion.

- Precision and Automation: Integration of real-time monitoring, closed-loop controls, and robotics to ensure consistent quality and reduce labor costs.

- Recycling and Circular Economy: Greater emphasis on recycled content and closed-loop production to minimize environmental impact.

- Customization: Growth in demand for custom colors, finishes, and functional additives (e.g., antimicrobial, UV-blocking, flame-retardant properties).

How will these trends affect your extrusion project?

Staying informed on material innovations, process improvements, and regulatory changes can help you future-proof your product designs and supply chain. Consult with experienced extruders to leverage new capabilities and maximize your competitive advantage.

Get Started: Connect with Leading Polymer Extrusion Companies

Ready to source high-quality extruded plastic products or develop a custom extrusion solution for your application? Explore our directory to identify and compare vetted extrusion suppliers based on your technical requirements, industry, and location. Whether you need medical-grade tubing, architectural profiles, or specialty films, our platform streamlines your supplier search and accelerates your time to market.

- Compare supplier capabilities, certifications, and project portfolios

- Request quotes and technical information using a unified RFQ form

- Access expert advice to optimize material selection and manufacturing processes

For more resources, guides, and industry news, continue browsing our website or contact our team for personalized assistance. With the right information and partners, you can unlock the full potential of polymer extrusion for your next project.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services