A plastic strip is a plastic shape made from continuous fabrication processes. There are a variety of plastic strips, and they are often placed in doorways for climate control in industries and public places. Many of the plastic strip varieties are characterized by narrowness and length.Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Crafted Plastics Inc. open_in_new

Location: Sheboygan, WI

Crafted Plastics has served the plastics extrusion needs of manufacturers and distributors worldwide since 1982. We craft plastics from a wide array of thermoplastics and are able to extrude basic to complex profiles. Whether you need products made from polyethylene, polycarbonate, polypropylene, PVC or acrylic, we’re your source for extruded plastic profiles or tubing. Call us soon; we look...

Pexco open_in_new

Location: Alpharetta, GA

Pexco has been a leader in custom plastic extrusion and injection molding, delivering innovative solutions for diverse markets and applications. We have six in-house tool and die centers and expertise in processing over 500 different resins and blends. We specialize in high-performance fluoropolymers, thermoplastics, and elastomers, delivering reliable performance in the most demanding...

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Plastic Strip Manufacturers

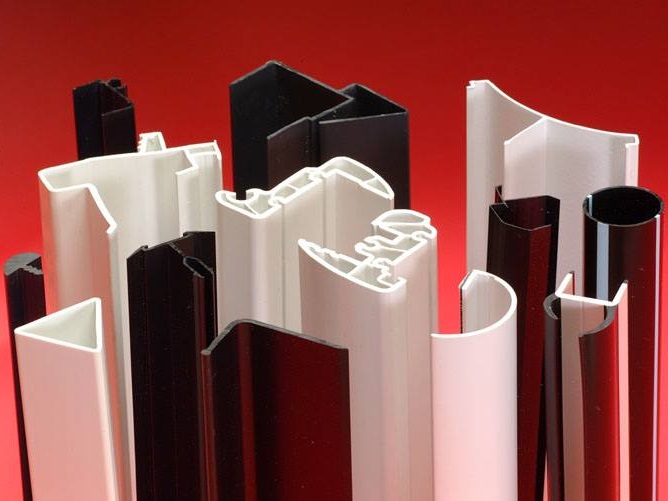

Plastic strips are versatile components essential to a wide range of industries, offering cost-effective and reliable solutions for building trim, collators for nails in nail guns, furniture components, weatherproofing, packaging, and countless custom applications. Whether you are an OEM, contractor, industrial buyer, or designer seeking custom extruded plastics, understanding the types, manufacturing processes, and applications of plastic strips is crucial for making the best purchasing decision.

Rigid plastic strips are engineered from a variety of polymer materials, including low-density and high-density polystyrene, PET (polyethylene terephthalate), polyethylene, polypropylene, acrylic, polycarbonate, and PVC (polyvinyl chloride), among others. The selected material determines the strip’s properties, such as durability, UV resistance, impact strength, flexibility, and suitability for indoor or outdoor use. For example, PVC is valued for its resistance to ultraviolet rays, making it ideal for exterior installations, while PET and HDPE are prized for their chemical resistance and strength.

What Are Plastic Strips?

Common Uses and Key Advantages

Plastic strips, sometimes referred to as extruded plastic strips or plastic edging strips, are narrow, elongated profiles made from thermoplastic materials. They play a pivotal role in a multitude of applications, including:

- Building and architectural trim

- Weather-stripping for doors and windows

- Machine and equipment protectors

- Furniture assembly and reinforcement

- Spacers, dividers, and gaskets in packaging

- Plastic strip curtains for warehouse and cold storage

- Electrical insulation and cable management

- Collators for nail guns in construction tools

- Signage, display edging, and retail fixtures

Buyers often search for the ideal plastic strip for their project by considering factors such as material type, thickness, width, rigidity, chemical resistance, and custom extrusion capabilities. Are you looking to find high-performance plastic strips for weatherproofing, or do you need low-cost plastic trim for furniture manufacturing? Identifying your primary use case will help narrow your options and ensure you select the most suitable product for your requirements.

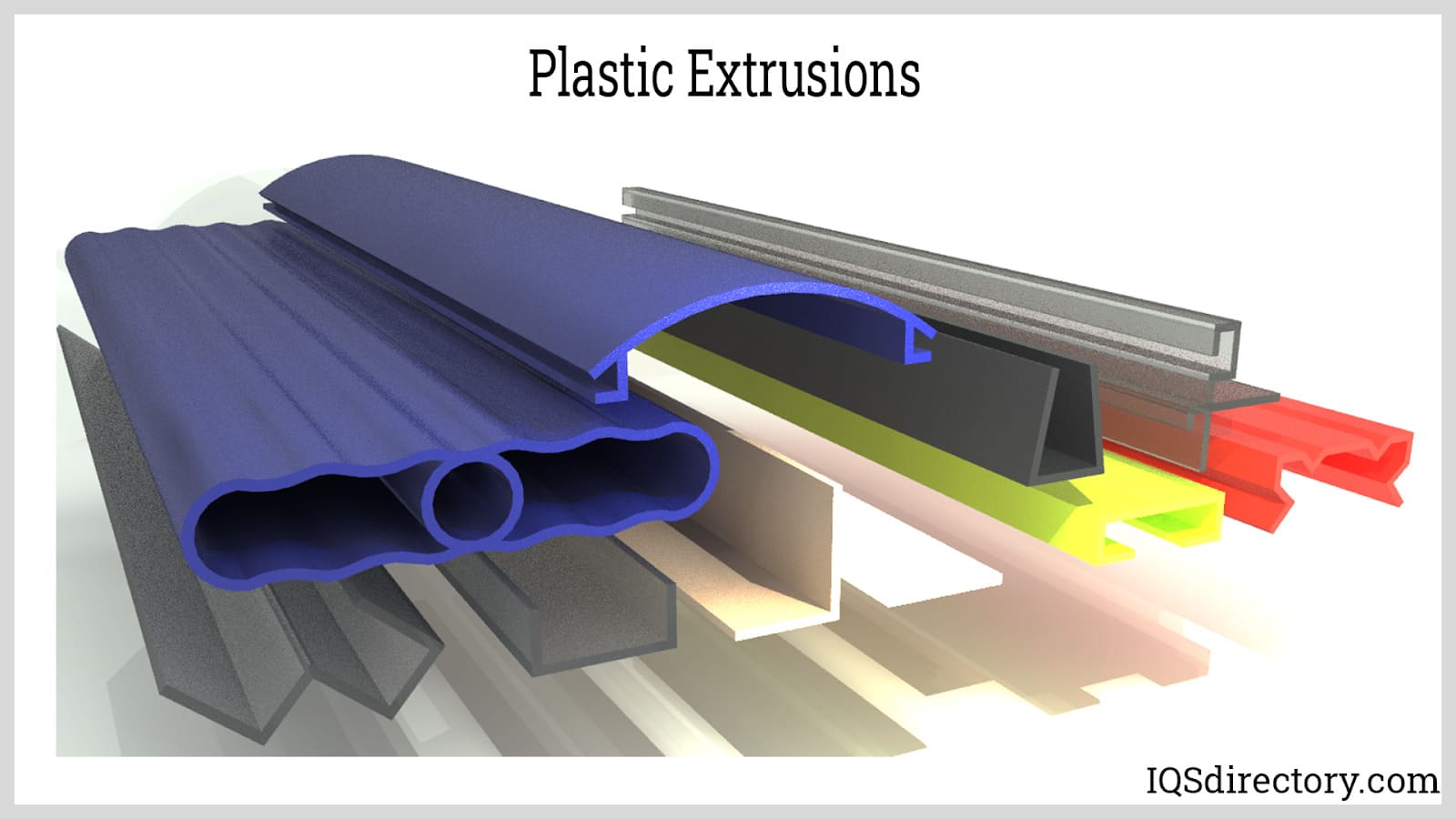

How Are Plastic Strips Manufactured?

The Plastic Extrusion Process Explained

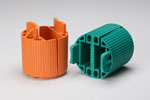

Plastic strips are primarily manufactured via plastic extrusion, a continuous, high-volume production process used to create profiles with consistent cross-sectional shapes. The extrusion method ensures tight tolerances, uniformity, and cost efficiency—making it the preferred approach for producing both standard and custom plastic strips.

The process begins with the selection of raw plastic resin, typically in granulate or pellet form. These granulates are gravity-fed into a hopper, which sits above the extruder. As the plastic material enters the extruder, it drops onto a rotating screw powered by an electric motor. The screw mechanism conveys the resin through a heated barrel, where it is gradually melted and mixed with any required additives, such as UV stabilizers, colorants, or flame retardants.

As the screw advances, its channel narrows, compressing, melting, and homogenizing the plastic. The molten polymer is then forced through a screen pack to filter out impurities before passing through a precision die. The die determines the shape and profile of the final plastic strip product—whether flat, rounded, angled, slotted, or custom-engineered. After exiting the die, the extruded strip is pulled along a conveyor and cooled, often using water baths, air cooling, or rollers, depending on the material and profile design.

Key advantages of extrusion manufacturing include the ability to produce long, continuous lengths, minimal material waste, and the flexibility to create complex and custom profiles at scale. For buyers in need of bulk plastic strips, or those seeking custom plastic extrusion services, this process offers a reliable and cost-effective solution.

Types of Plastic Strips: Material Options and Performance Characteristics

Choosing the right material for your plastic strips is essential for optimal performance in your specific application. Below are the most commonly used types of plastic strips, each with its unique strengths:

Polypropylene (PP) Plastic Strips

Polypropylene strips are renowned for their excellent chemical resistance, fatigue endurance, and moderate temperature tolerance. They are widely used in industrial and chemical processing environments, packaging, and applications requiring repeated flexing. However, due to a relatively narrow thermoforming temperature window, forming PP can be challenging, and webbing may occur during processing. The semi-crystalline nature of PP means it can shrink after forming, so fillers like talc are often added to enhance stability and reduce shrinkage.

- Best for: Chemical resistance, reusable packaging, flexible edging, and automotive components

- Considerations: Not ideal for high-heat environments; may require stabilization additives

Acrylonitrile Butadiene Styrene (ABS) Plastic Strips

ABS plastic strips stand out for their versatility, ease of forming, and wide temperature processing window. With superior dimensional stability, impact resistance, and machinability, ABS is a popular choice for automotive interiors, appliance housings, furniture edging, and consumer goods. ABS strips are easy to trim and finish, making them a preferred option for applications where appearance and precision are important.

- Best for: Automotive trim, furniture, consumer products, electronic enclosures

- Considerations: Moderate UV resistance, may require UV stabilizers for outdoor use

Acrylic (PMMA) Plastic Strips

Acrylic strips, made from polymethyl methacrylate (PMMA), are highly valued for their optical clarity, resistance to UV light, and increased impact resistance compared to glass. These strips are easy to machine, polish, and screen print, making them ideal for signage, displays, lighting fixtures, and architectural accents. Acrylic’s weatherability and color retention also make it suitable for outdoor use.

- Best for: Retail displays, signage, glazing, lighting, architectural details

- Considerations: Can be brittle under high impact; not suitable for heavy load-bearing applications

PVC (Polyvinyl Chloride) Plastic Strips

PVC plastic strips are among the most widely used due to their balance of strength, rigidity, and cost-effectiveness. PVC offers excellent chemical and weather resistance, making it ideal for outdoor trim, weather-stripping, and industrial barriers. It is easy to fabricate, weld, and thermoform, though it may become brittle at low temperatures.

- Best for: Door and window seals, wall and floor trim, industrial curtains, fencing

- Considerations: May require plasticizers for increased flexibility; not ideal for extremely cold environments

High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) Strips

HDPE and LDPE plastic strips are popular for their outstanding chemical resistance, low moisture absorption, and excellent impact strength. HDPE strips are rigid and durable, making them suitable for outdoor use, agricultural applications, and industrial liners. LDPE strips, on the other hand, are highly flexible and can be used for sealing, cushioning, and packaging.

- Best for: Agricultural barriers, utility liners, flexible seals, packaging strips

- Considerations: Lower temperature resistance compared to other engineering plastics

Polycarbonate Plastic Strips

Polycarbonate strips offer high impact resistance, optical clarity, and excellent dimensional stability. These properties make them a preferred choice for protective guards, machine shields, and safety glazing. Polycarbonate is also UV-stabilized for outdoor use.

- Best for: Protective barriers, machine guards, safety glazing, electronic components

- Considerations: Higher cost than other plastics; can scratch more easily than acrylic

Applications of Plastic Strips: Industry Use Cases and Solutions

Plastic strips are found in virtually every sector, from construction and manufacturing to retail, healthcare, and logistics. Their adaptability, performance, and value make them indispensable across diverse applications. Below, discover how various industries leverage extruded plastic strips:

Construction and Architecture

- Fences and fencing slats for privacy and security

- Edging strips for landscaping and garden beds

- Weather-stripping for doors and windows to improve energy efficiency

- Framing, posts, and tubing for lightweight structural elements

- Piping and conduit for electrical and plumbing systems

- Window frames and glazing beads for residential and commercial buildings

- Expansion joints and concrete formwork

Industrial and Manufacturing

- Machine trim and protective bumpers

- Tracks for conveyor belts and assembly lines

- Equipment guards and protectors to enhance workplace safety

- Electrical wire covers, cable management, and raceways

- Seals, gaskets, and vibration dampeners

- Plastic spacers for assembly and kitting

Commercial, Retail, and Logistics

- Plastic strip curtains for cold storage, warehouses, and clean rooms

- Retail display edging and shelf management strips

- Point-of-purchase (POP) signage holders

- Packaging dividers and protective strips for shipping containers

- Floor guides and wall bumpers

Automotive and Transportation

- Interior trim and panel edging

- Protective seals and weather-stripping for doors and windows

- Wire harness covers and insulation

- Exterior trim and decorative accents

Specialty and Custom Applications

- Medical device assembly and sterilizable covers

- Clean room and laboratory partitions

- Recreational and sports equipment

- Custom profiles for OEM components

Benefits of Plastic Strips: Why Choose Extruded Plastics?

When comparing plastic strips to traditional materials like metal or wood, buyers often ask: What are the key advantages of plastic strips? The answer lies in a combination of unique benefits that make extruded plastic strips the material of choice for demanding environments and cost-sensitive projects alike:

- Low Maintenance: Resistant to rot, corrosion, and insect damage, requiring little to no upkeep over time.

- Cost-Effective: Lower material and installation costs compared to metal, wood, or glass alternatives.

- Energy Efficiency: Prevents 80-90% of air loss through doors, contributing to reduced utility bills.

- Enhanced Hygiene: Easy to clean and sanitize; ideal for food processing, healthcare, and clean room environments.

- Reduces Product Spoilage: Maintains temperature control and prevents contamination in cold storage and warehouses.

- Equipment Longevity: Reduces wear and tear on switches, motors, and compressors by improving environmental control.

- Pollution Control: Restricts dust, pollutants, and pests from entering controlled spaces.

- Weather Resistance: Performs exceptionally well in outdoor environments, even when exposed to UV, rain, and temperature extremes.

- Ease of Fabrication: Can be cut, drilled, machined, and welded to suit a wide variety of custom needs.

- Impact Resistance: Withstands knocks and bumps in busy environments.

- Strength and Rigidity: Supports structural applications where durability is paramount.

- Customizability: Available in a variety of colors, finishes, sizes, and profiles to meet aesthetic and functional requirements.

Do you need custom plastic strip profiles for a unique project? Many manufacturers provide custom plastic extrusion services to accommodate demanding specifications, including co-extrusion, dual-durometer strips, colored or clear plastics, and specialty additives for flame, static, or UV resistance.

How to Choose the Best Plastic Strip Manufacturer: Key Questions and Selection Criteria

With so many plastic strip suppliers and extruders available, how do you choose the right partner for your business? Here are some key factors and questions to ask as you evaluate plastic strip manufacturers:

- Do they offer a wide variety of materials and extrusion capabilities? (PVC, polycarbonate, acrylic, HDPE, LDPE, etc.)

- Can they provide custom profiles, finishes, and colors?

- What are their minimum order quantities and lead times?

- Do they have experience serving your industry or application?

- Are samples and prototyping services available?

- What quality certifications do they hold?

- Can they assist with design and engineering support?

- What are their pricing structures and delivery options?

- Do they offer sustainable or recycled plastic options?

To ensure you achieve the most constructive outcome when purchasing plastic strips, compare several companies using our directory of plastic strip manufacturers. Each supplier has a dedicated business profile page that highlights their materials, extrusion capabilities, certifications, and areas of expertise. You can also use the integrated contact form to request further information, samples, or a custom quote. Use our proprietary website previewer to quickly compare manufacturers and streamline your sourcing process. Our convenient RFQ (Request for Quote) form allows you to reach out to multiple plastic strip suppliers at once, saving you time and effort in your supplier search.

Frequently Asked Questions About Plastic Strips

What are the most durable plastic strip materials for outdoor use?

PVC, HDPE, and polycarbonate strips offer excellent weather resistance, UV stability, and impact strength—making them ideal for fencing, trim, and industrial barriers exposed to sunlight and the elements.

Can plastic strips be recycled or made from recycled materials?

Many plastic strips can be manufactured from recycled plastics, such as rPET or post-consumer HDPE, supporting sustainability initiatives. Ask your supplier about eco-friendly extrusion options and recycling programs for end-of-life strips.

How do I choose the right dimensions and profile for my plastic strip application?

Consider factors like width, thickness, length, rigidity, color, and whether you need custom features such as pre-drilled holes, adhesive backing, or dual-material co-extrusions. Share your application details with your manufacturer for guidance on the optimal profile.

Can I order custom colors or finishes for plastic strips?

Most manufacturers offer a wide range of colors, surface textures, and finishes, including matte, gloss, textured, or clear. Custom color matching is also available for branding or aesthetic requirements.

What is the typical lead time for plastic strip orders?

Lead times vary depending on order size, complexity, and tooling requirements. Standard profiles may ship within days, while custom extrusions or large orders may require several weeks. Confirm lead times with your chosen supplier.

Get Started: Find the Right Plastic Strip Solution for Your Needs

Ready to source high-quality plastic strips for your next project? Start by identifying your primary application and required material properties. Next, compare suppliers using our comprehensive directory and reach out for quotes, samples, or expert guidance. Whether you need off-the-shelf plastic strips, custom extrusion solutions, or sustainable recycled options, the right manufacturer can deliver the performance, value, and reliability you need.

Still have questions? Explore our resources on plastic extrusion, material selection, and custom plastic fabrication to help you make an informed purchasing decision. For tailored assistance, contact our plastic extrusion specialists—we’re here to help you find the plastic strip solution that fits your exact requirements.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services