Different materials hold different advantages. Acrylics, for example, offer exceptional chemical resistance while polystyrene offers good adhesive capabilities. PVC is the most common type of plastic used for plastic profiles due to its flexibility, allowing it to be used for numerous applications. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Crafted Plastics Inc. open_in_new

Location: Sheboygan, WI

Crafted Plastics has served the plastics extrusion needs of manufacturers and distributors worldwide since 1982. We craft plastics from a wide array of thermoplastics and are able to extrude basic to complex profiles. Whether you need products made from polyethylene, polycarbonate, polypropylene, PVC or acrylic, we’re your source for extruded plastic profiles or tubing. Call us soon; we look...

Pexco open_in_new

Location: Alpharetta, GA

Pexco has been a leader in custom plastic extrusion and injection molding, delivering innovative solutions for diverse markets and applications. We have six in-house tool and die centers and expertise in processing over 500 different resins and blends. We specialize in high-performance fluoropolymers, thermoplastics, and elastomers, delivering reliable performance in the most demanding...

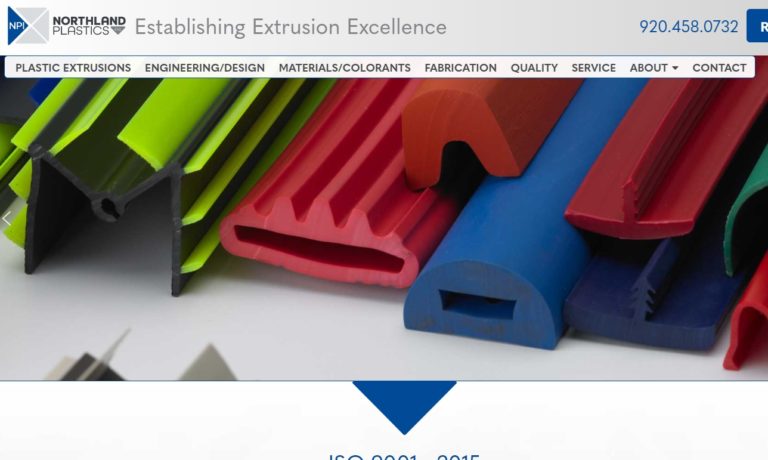

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Plastic Profile Manufacturers

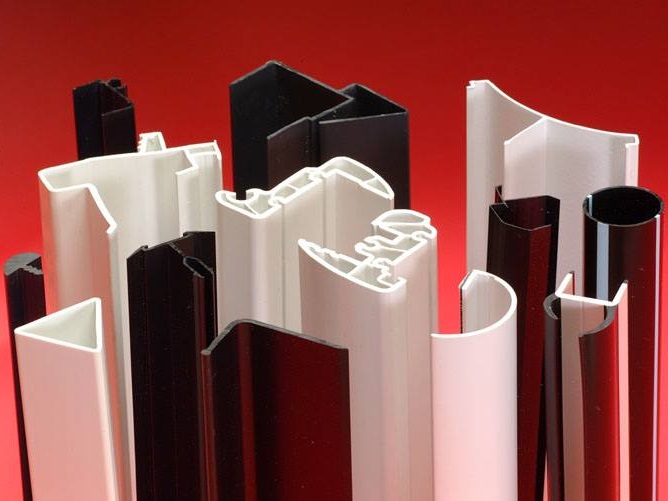

Plastic profiles are available in a wide range of shapes and sizes including shapes such as thin film, rods, wire sheets, trim, channels, rods, tubing and gaskets.

Plastic profile extrusions can be hot extruded, cold extruded or warm extruded through a die in either indirect or direct extrusion process. Each of these processes has its own benefits and drawbacks.

Extruded plastic profiles are highly versatile and can be designed for specific applications such as pipes, hosing, fridge and freezer parts, packaging, gas and water piping, protective covers, light diffusers, display stands and point of sale holders.

Serving industries including construction, medical, aerospace, office furniture, manufacturing and transportation, most plastic profile extrusion companies also offer secondary services such as heat treating, printing, labeling, welding, anodizing and electroplating.

The extrusion process begins with raw plastic pellets or flakes being fed into a hopper placed atop a closed extruding channel; gravity feeds the raw plastic material down into the extruding channel.

Running through the length of the channel is a screw conveyor that moves the raw plastic along toward the opposite end, shearing and heating the plastic through friction. Plastic pellets plasticize, or melt, as they move through the conveyor. As they near the end of the channel, the molten plastic leaves the screw and travels through a screen pack in order to remove any contaminants.

The screens are reinforced by a breaker plate, which is a thick metal puck with many holes drilled through it. A die is secured on the end of the conveyor channel, which forms the molten plastic into a specific profile as it is pushed, or extruded, through by the screw conveyor. The newly formed plastic profile is cooled, pulled through by a series of conveyors and cut to appropriate lengths. In this way plastic profiles are manufactured quickly and in fairly high volumes.

Plastic profiles can be made using various types of extrusion processes including reverse extrusion, in which the thermoplastic material is made to flow in the opposite direction of the screw, and coextrusion, in which multiple layers are extruded together.

In addition there are two main ways in which plastic profiles can be extruded: hot working and cold working. In cold working, plastic deformation is imparted to the thermoplastic material at room temperature or near room temperature. Hot working uses heated thermoplastic materials with good deformability.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services