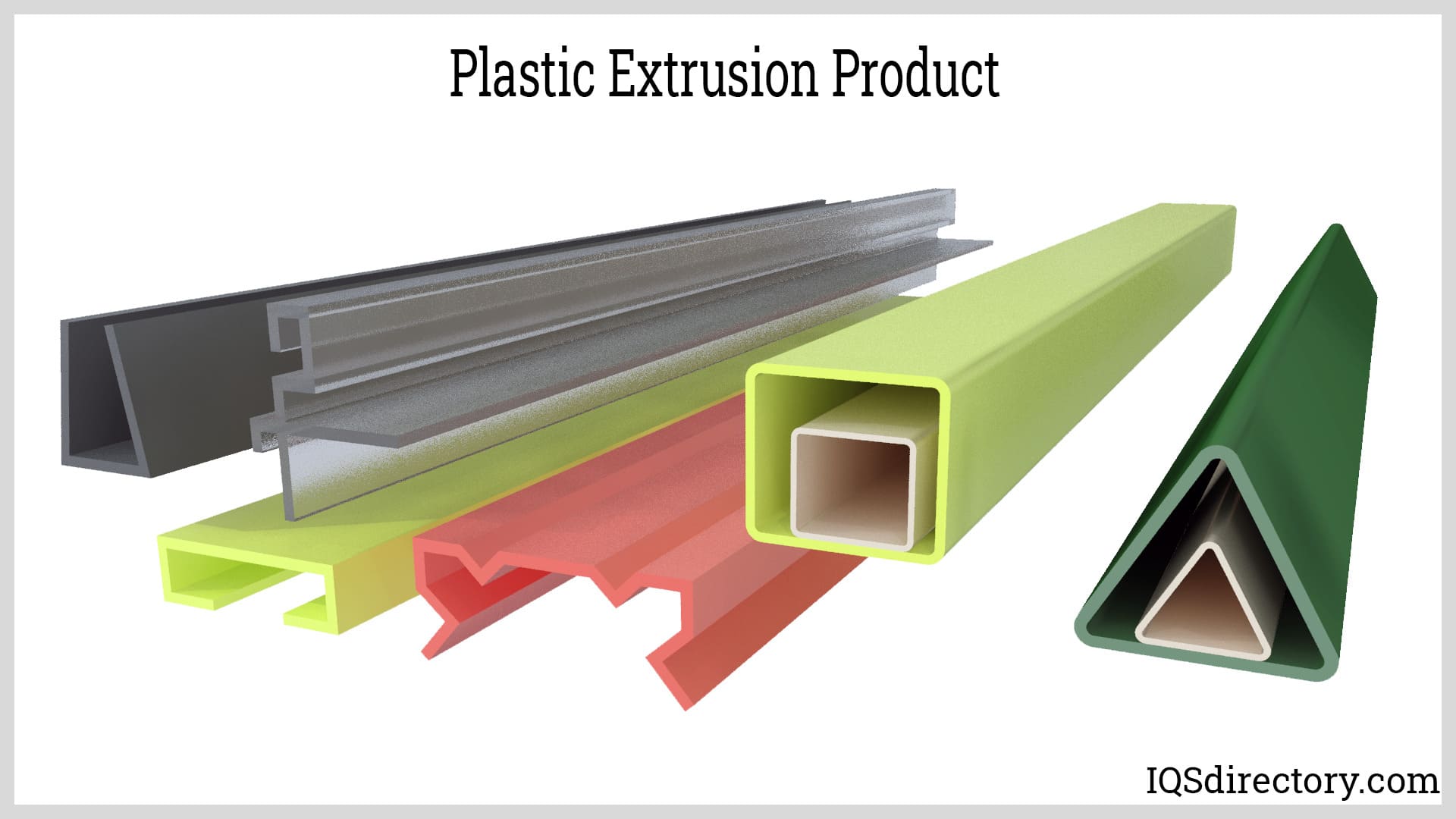

Polymer extrusion is a widely used production method in the plastics sector since it is accessible and simple to use, whether it be to produce one hundred yards of pipe-tubing, plastic sheets, or a thousand crazy straws. The plastic’s molecules are also aligned during extrusion to increase the piece’s strength along its length. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Crafted Plastics Inc. open_in_new

Location: Sheboygan, WI

Crafted Plastics has served the plastics extrusion needs of manufacturers and distributors worldwide since 1982. We craft plastics from a wide array of thermoplastics and are able to extrude basic to complex profiles. Whether you need products made from polyethylene, polycarbonate, polypropylene, PVC or acrylic, we’re your source for extruded plastic profiles or tubing. Call us soon; we look...

Pexco open_in_new

Location: Alpharetta, GA

Pexco has been a leader in custom plastic extrusion and injection molding, delivering innovative solutions for diverse markets and applications. We have six in-house tool and die centers and expertise in processing over 500 different resins and blends. We specialize in high-performance fluoropolymers, thermoplastics, and elastomers, delivering reliable performance in the most demanding...

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Extruded Plastic Manufacturers

Comprehensive Guide to the Plastic Extrusion Process: Materials, Applications, and Manufacturer Selection

Plastic extrusion is a cornerstone manufacturing process in the plastics industry, enabling the mass production of a diverse range of plastic products with precise dimensions and consistent quality. By melting plastic material, pressing it through a specialized die to form a continuous profile, and then cutting it to custom lengths, extrusion technology delivers unmatched efficiency for both standard and complex shapes. This method is ideally suited for applications requiring a uniform cross-section, making it the preferred choice for producing items such as plastic piping, sheeting, weather stripping, wire insulation, window profiles, custom seals, and adhesive tape. Due to its cost-effectiveness, scalability, and high output rates, plastic extrusion remains a dominant solution for industries seeking reliable, high-volume manufacturing of thermoplastic components.

What Is Plastic Extrusion? Understanding the Basics

Plastic extrusion is a continuous, high-volume process in which raw plastic—often in the form of resin pellets or granules—is melted and forced through a die to create long products with a consistent cross-sectional shape. The process involves several key stages: feeding the polymer material into the extruder, melting and mixing the material using heat and mechanical shear, shaping the molten plastic through a die, cooling the formed profile, and cutting it to the desired length. This versatile process is widely used for manufacturing everything from basic tubing and profiles to advanced, custom-engineered components for demanding industries.

Wondering how plastic extrusion differs from injection molding or blow molding? Plastic extrusion is uniquely suited for creating continuous lengths of product—think pipes, sheets, or films—whereas injection molding is ideal for discrete, complex parts, and blow molding specializes in hollow objects like bottles. If you’re exploring which process fits your project needs, consider the volume, geometry, and material requirements for your application.

Types of Plastic Extrusion Materials

Choosing the right plastic material for extrusion is vital for ensuring product performance, durability, and cost-efficiency. The most commonly extruded plastics are thermoplastics—materials that soften when heated and harden upon cooling—but thermosets can also be processed by specialized means. The following are some of the most popular and high-performance materials used in plastic extrusion:

PVC (Polyvinyl Chloride)

Polyvinyl chloride (PVC) stands out as one of the most versatile and widely used plastics in extrusion manufacturing. It offers a unique combination of durability, chemical resistance, and cost-effectiveness, making it ideal for applications such as plumbing pipes, window frames, cable insulation, medical tubing, and weather stripping. Rigid PVC is known for its strength and structural integrity, while the addition of plasticizers transforms it into flexible PVC for applications requiring pliability, such as hoses and seals. PVC is also flame-retardant and exhibits excellent resistance to moisture and abrasion, further extending its range of industrial and consumer applications. Its ease of coloring and compatibility with additives make it a top choice for custom extruded profiles.

Polypropylene (PP)

Polypropylene (PP) is a lightweight, semi-crystalline thermoplastic polymer resin prized for its exceptional chemical resistance, high melting point, and excellent mechanical properties. Its high tensile and compressive strength, combined with low moisture absorption and outstanding dielectric performance, make it a preferred material for automotive components, laboratory equipment, packaging strips, and electrical insulation. Polypropylene is naturally translucent but can be easily colored or tinted to meet specific design requirements. In extrusion, PP’s flexibility and processability enable the production of robust yet lightweight products, including piping, medical devices, and consumer goods. Its resistance to acids, solvents, and UV degradation ensures long-lasting performance in both indoor and outdoor environments.

Polyethylene (PE)

Polyethylene is one of the most prevalent plastics used in extrusion, available in various forms such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE). Each type offers distinct advantages: HDPE excels in strength and chemical resistance, making it ideal for water and gas pipes, geomembranes, and industrial containers; LDPE provides flexibility and clarity for products like plastic bags, films, and sheeting; LLDPE offers a balance of strength and flexibility for stretch wrap and packaging. Polyethylene’s low cost, easy processability, and recyclability further enhance its appeal for large-scale extrusion applications.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a tough, impact-resistant engineering thermoplastic commonly used in extrusion for automotive trim, appliance housings, protective profiles, and consumer electronics casing. It combines the strength and rigidity of acrylonitrile and styrene polymers with the toughness of polybutadiene rubber, resulting in products that withstand mechanical stress and repeated use. ABS extrusions are easily machined, welded, and painted, making them ideal for custom applications where aesthetics and durability are equally important. If you’re seeking a material for high-strength, visually appealing profiles, ABS is an excellent choice.

Nylon (Polyamide)

Nylon is a synthetic polyamide valued for its high mechanical strength, abrasion resistance, and low friction properties. In the extrusion process, nylon is used to produce cable ties, tubing, gear components, and industrial brushes. Nylon’s resistance to oils, fuels, and solvents makes it suitable for automotive and machinery applications, while its flexibility and resilience ensure long service life in dynamic environments. For applications requiring tough, wear-resistant extruded parts, nylon offers a compelling solution.

Polycarbonate (PC)

Polycarbonate is a high-performance, transparent thermoplastic known for its outstanding impact resistance and optical clarity. It is frequently extruded into sheets, panels, safety glazing, and protective covers for electronics. Polycarbonate’s ability to withstand significant physical force without cracking, along with its flame retardancy and UV stability, makes it indispensable for architectural, automotive, and security applications. If your project demands a combination of strength, transparency, and weather resistance, polycarbonate extrusions are worth considering.

Plastic Extrusion Process Basics

Nearly all extruded plastics fall into the thermoplastics category, though some thermosets can be extruded via specialized heating methods. Thermoplastics are subdivided into three broad groups based on performance and cost:

- High-performance plastics: These are engineered for demanding conditions, offering superior thermal stability, mechanical strength, and resistance to chemicals. Examples include polyether ether ketone (PEEK), polyether ketone (PEK), and fluoropolymers, which are extensively used in aerospace, medical device, and automotive sectors for components exposed to extreme environments.

- Engineering plastics: These materials strike a balance between performance and economy. Common engineering plastics in extrusion include TPE (thermoplastic elastomers), ABS, nylon, and polycarbonate. They are chosen for their enhanced mechanical properties, toughness, and specialty characteristics without the high cost of high-performance resins.

- Commodity plastics: These are widely used, cost-effective materials such as PVC, polypropylene, and polyethylene. Their versatility makes them suitable for consumer goods, construction, packaging, and household products.

The molecular structure of the chosen polymer—whether amorphous or crystalline—directly influences the final product’s properties. Amorphous plastics, such as PVC, ABS, and polycarbonate, feature disordered polymer chains that endow them with flexibility, elasticity, and excellent impact resistance. These materials are less prone to shrinkage and can absorb energy without cracking, making them ideal for profiles, seals, and covers.

Crystalline plastics, including HDPE and polypropylene, possess highly ordered molecular structures that provide superior strength, stiffness, and heat resistance. These plastics excel in load-bearing and high-temperature applications but may exhibit less impact resistance and a tendency to shrink during cooling. Understanding the interplay between polymer structure and extrusion process parameters is essential to achieving optimal performance in the finished product.

Are you evaluating which plastic material best suits your extrusion project? Consider your application’s mechanical, chemical, and thermal requirements, as well as regulatory compliance, color, and finish. For help selecting the best thermoplastic or thermoset for your needs, contact our experts or use our material selection guide.

Plastic Extrusion Applications and Use Cases

The versatility of the plastic extrusion process supports a broad array of end-use applications across multiple industries. Here are some of the leading use cases and industry sectors benefiting from custom and standard plastic extrusion:

- Construction and Building: Production of window profiles, door frames, weather stripping, conduit, and siding using durable extruded plastics like PVC and HDPE for excellent weather resistance and structural integrity.

- Automotive and Transportation: Manufacturing of trim, wire insulation, tubing, and seals where chemical resistance, flexibility, and impact absorption are critical. Engineering plastics such as ABS and polypropylene are widely used in these sectors.

- Electrical and Electronics: Creation of cable jacketing, insulating channels, and housings for sensitive components. Polycarbonate and polyethylene are preferred for their dielectric properties and safety performance.

- Medical Devices: Extrusion of medical-grade tubing, IV lines, catheters, and protective sheaths using biocompatible polymers such as PVC and polypropylene.

- Consumer Goods: Everyday products such as garden hoses, appliance trim, decorative edging, and packaging films are produced through efficient extrusion methods.

- Packaging: Creation of films, sheets, and containers for food, pharmaceuticals, and retail using LDPE, LLDPE, and multi-layer coextrusion for barrier performance.

Looking for a specific plastic extrusion solution for your industry? Explore our custom plastic profiles or request a quote to discuss your unique requirements.

Specialty Plastic Extrusion Processes

For projects that demand advanced features, higher productivity, or enhanced material properties, a range of specialty extrusion processes are available. These specialized methods deliver tailored solutions for complex applications:

- Coextrusion: Simultaneous extrusion of two or more different polymers to create multi-layered products. Coextrusion enhances mechanical, barrier, and aesthetic properties, enabling the production of laminated products, dual-durometer seals, and layered films used in packaging, automotive, and medical markets.

- Overjacketing: Application of a protective extruded plastic layer over wire, cable, or other elements. This process improves abrasion, moisture, and chemical resistance, making it essential for electrical insulation, telecom cables, and industrial wiring.

- Tubing Extrusion: Creation of hollow plastic tubes or pipes using dies with inner mandrels or pins. Tubing extrusion is vital for manufacturing medical tubing, irrigation pipes, and conduit, where both internal and external dimensions must be tightly controlled. Air may be injected during the process to maintain shape and prevent collapse.

- Blown Film Extrusion: Production of plastic film products (such as plastic bags, shrink wrap, and agricultural films) by extruding molten plastic through a circular die and inflating it to form a thin, continuous tube. The stretched film aligns polymer chains for improved strength and flexibility.

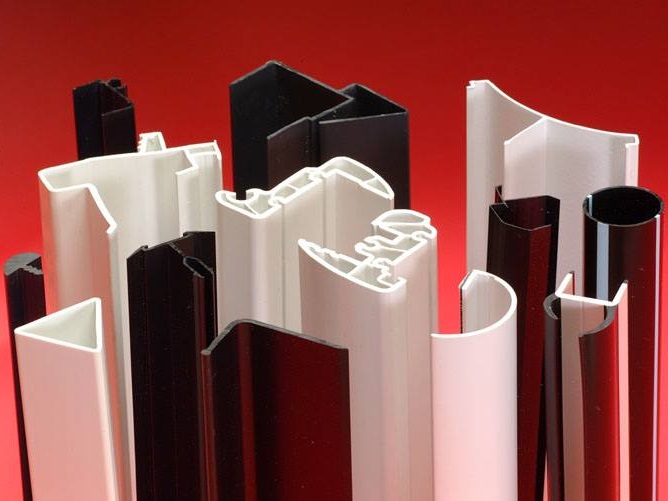

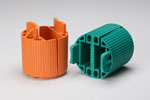

- Profile Extrusion: Custom-designed dies shape the plastic into complex cross-sections, enabling the creation of window profiles, trim, weather seals, and decorative moldings tailored to specific customer requirements.

Curious about which extrusion process is right for your application or how specialty extrusion can add value to your products? Ask our team or review our comprehensive guide to plastic extrusions to find detailed process comparisons and selection criteria.

Key Benefits of Plastic Extrusion Manufacturing

Why choose extrusion for your plastic manufacturing needs? Plastic extrusion offers a host of advantages for OEMs, fabricators, and end users alike:

- Cost Efficiency: High production speeds, low material waste, and energy-efficient processing reduce manufacturing costs, making extrusion ideal for both large-scale and custom runs.

- Design Flexibility: The process accommodates a vast range of shapes, sizes, and material blends, allowing for highly customized solutions.

- Consistent Quality: Continuous production yields uniform products with tight dimensional tolerances and repeatable properties.

- Material Versatility: Compatible with a wide array of thermoplastics, including specialty compounds and sustainable, recycled resins.

- Scalability: Easily scaled from prototyping to full-scale production, supporting everything from R&D samples to millions of linear feet.

- Customization: Integration of colorants, additives, reinforcements, and surface treatments in-line for tailored performance characteristics.

Are you evaluating the pros and cons of plastic extrusion versus other manufacturing methods? Consider the process’s unique strengths in terms of cost, quality, and customization, especially for continuous-profile products.

How to Choose the Right Extruded Plastic Manufacturer

Selecting the right extrusion partner is a critical step in achieving your project goals. To ensure a successful outcome when sourcing extruded plastic products or custom profiles, it’s essential to evaluate manufacturers based on experience, technical capabilities, quality control, and customer service. Here’s a proven approach to finding the best extruded plastic manufacturer for your needs:

- Define Your Requirements: Identify the material, dimensions, tolerances, performance criteria, and volume needed for your application. Consider regulatory standards and end-use conditions.

- Assess Manufacturer Capabilities: Review each manufacturer’s expertise in specific materials (e.g., PVC, polycarbonate, TPE), advanced extrusion processes (such as coextrusion or overjacketing), and ability to deliver value-added services like design assistance, prototyping, and secondary operations.

- Check Quality Assurance: Confirm adherence to industry certifications (ISO, UL, FDA, RoHS) and quality management systems. Ask for samples, references, or case studies illustrating past successes in similar projects.

- Compare Pricing and Lead Times: Request quotes from multiple manufacturers to compare pricing, minimum order quantities, and delivery timelines. Balance cost considerations with technical expertise and reliability.

- Evaluate Communication and Support: Choose a partner with responsive customer service, transparent project management, and a collaborative approach to problem-solving.

To simplify your search, leverage our comprehensive directory of extruded plastic manufacturers. Each company profile highlights specialties, material expertise, and process capabilities. Use our contact forms to request quotes, ask technical questions, or schedule consultations with multiple suppliers—all from one convenient platform. For quick insights, our proprietary website previewer lets you compare companies at a glance.

Ready to connect with leading plastic extrusion companies? Request a quote or submit your project details to receive tailored recommendations from trusted manufacturers.

Frequently Asked Questions About Plastic Extrusion

What factors influence the cost of plastic extrusion?

Plastic extrusion costs are affected by material selection, part complexity, tooling and die design, order volume, and required tolerances. Specialty materials or multi-layer coextrusion may raise costs, while high-volume production typically reduces per-unit pricing. Requesting multiple quotes helps identify the best value for your project.

Which plastic is the best for outdoor applications?

For products exposed to outdoor environments, consider UV-resistant and weatherable plastics such as HDPE, UPVC, and certain grades of polypropylene. Additives and coatings can further enhance resistance to sunlight, moisture, and temperature fluctuations.

Can recycled plastics be used in extrusion?

Yes, many extrusion manufacturers offer sustainable solutions using recycled or reprocessed plastics. Recycled HDPE, LDPE, and polypropylene are common choices, supporting eco-friendly product initiatives without compromising performance in many applications.

How are custom colors and finishes achieved with extrusion?

Colorants and surface modifiers are typically incorporated directly into the polymer melt during extrusion, allowing for a wide range of custom colors, textures, and gloss levels. Post-extrusion treatments such as embossing, printing, or laminating add further design options.

What are typical lead times for extruded plastic products?

Lead times depend on tooling complexity, material availability, and production volume. Standard profiles may ship within days, while custom projects involving new tooling or specialty materials may require several weeks. Early collaboration with your manufacturer helps ensure on-time delivery.

Still have questions? Contact our plastic extrusion specialists for expert advice, technical support, or personalized product recommendations.

Start Your Plastic Extrusion Project Today

Whether you’re launching a new product, optimizing an existing design, or sourcing a reliable manufacturer for high-volume production, the plastic extrusion process offers unmatched versatility, efficiency, and value. By understanding material options, specialty processes, and key decision factors, you can confidently specify and source the best extruded plastic products for your needs.

Explore our resources, compare top manufacturers, and request a quote to get started on your next extrusion project. For in-depth guidance, visit our Plastic Extrusions Resource Center.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services